Tomahawk Scout Cleaning and Preparation

![]() Clean

Clean

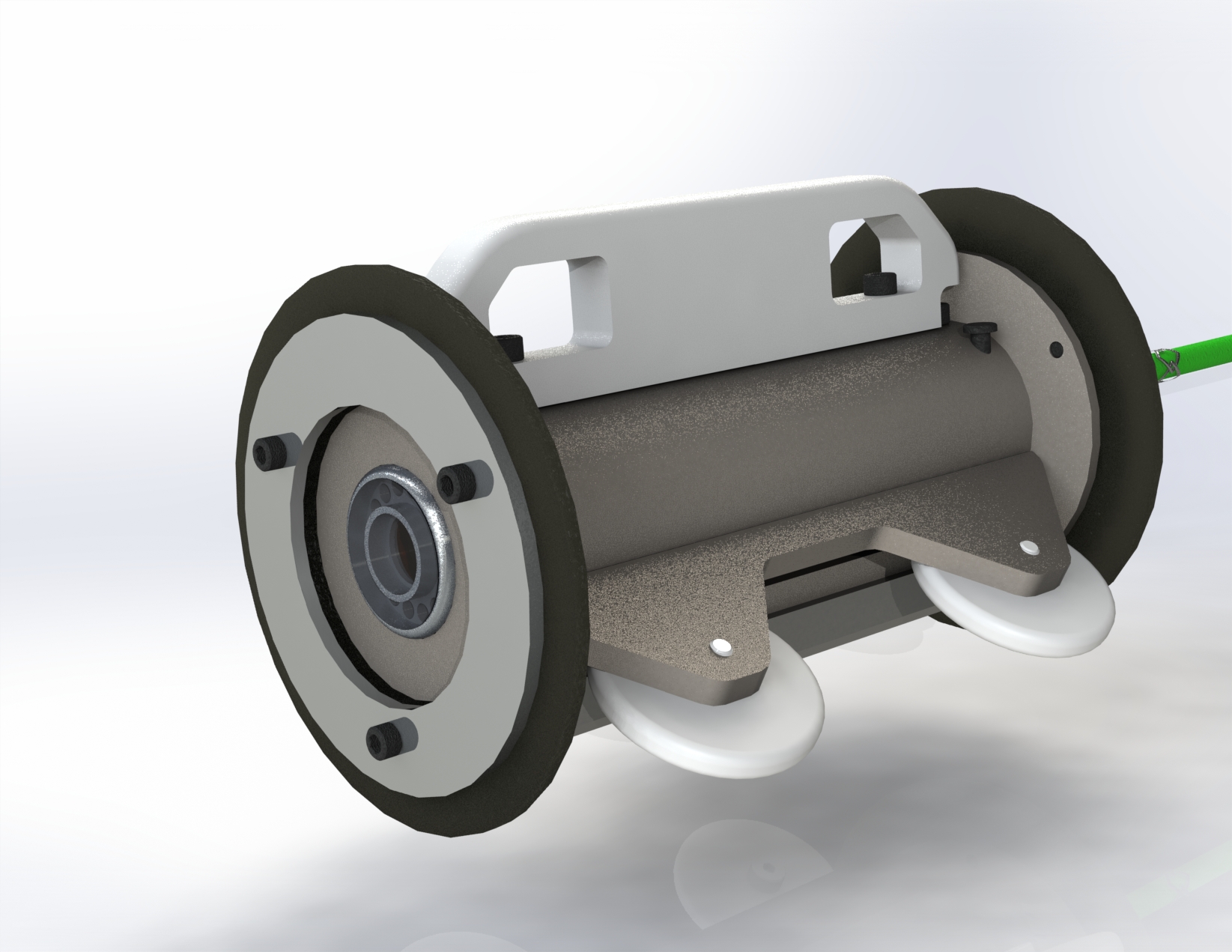

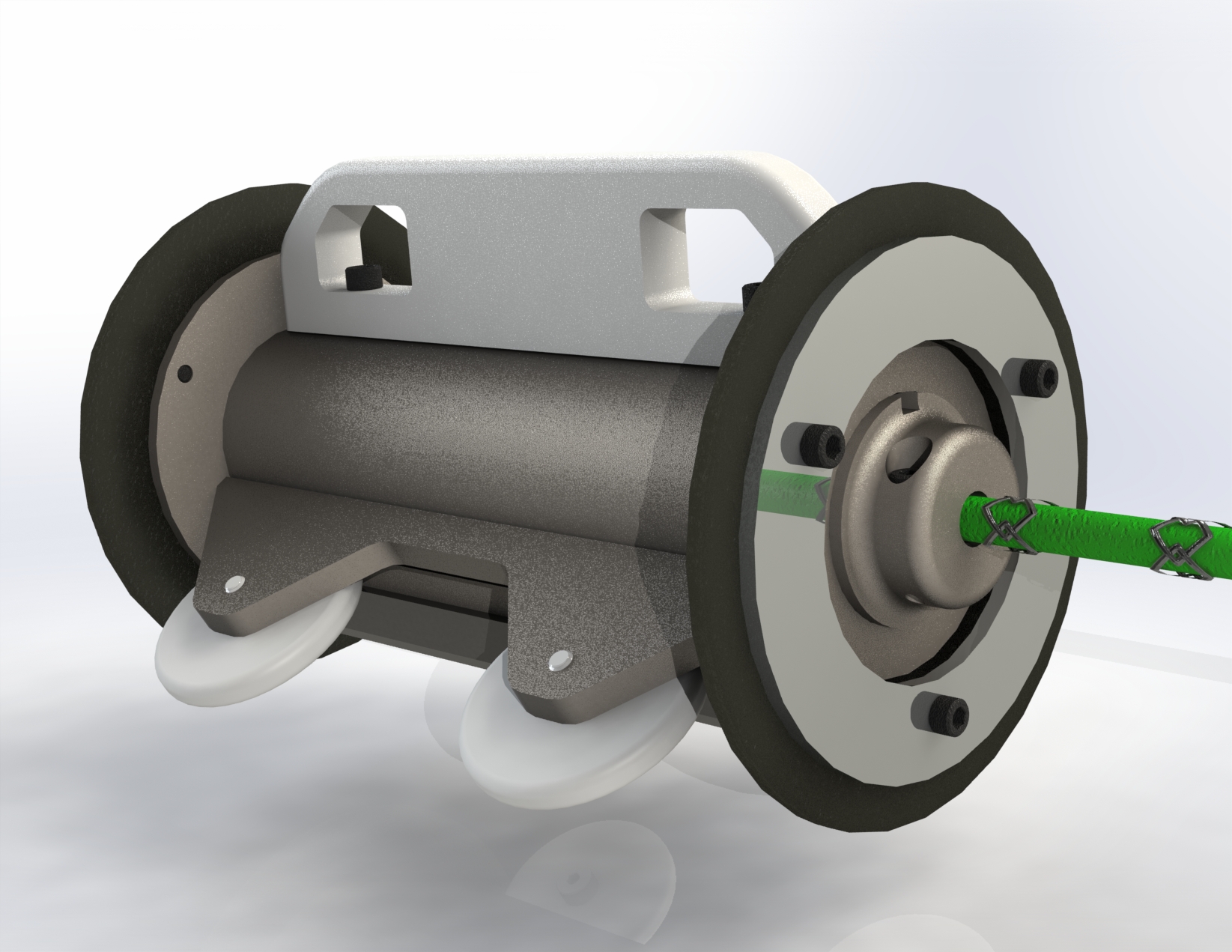

The innovative and patented Tomahawk Scout™ is an integral member of the Tomahawk™ System and is tasked with the concurrent preparation and inspection of the pipe interior following airborne abrasive cleaning. The airstream driven Scout does its job fast and efficiently utilizing CCTV capability to spot areas that require targeted cleaning and drying while observing the action in real time. The vaculating or drawing out effect produced by Scout can also aid in the discovery of trouble spots such as holes or cracks for immediate remediation. This is one versatile device!

The Scout can be used of pipe diameters from 100mm (4") to 300mm (12"). For a Tomahawk cleaning overview document which includes stone abrasives, vac tuck, access pit, Scout specifications and more, please click here.

Above: Tomahawk Scout™, with integrated CCTV camera, wheeled body and vaculating features

Vaculation of Pipeline Joints

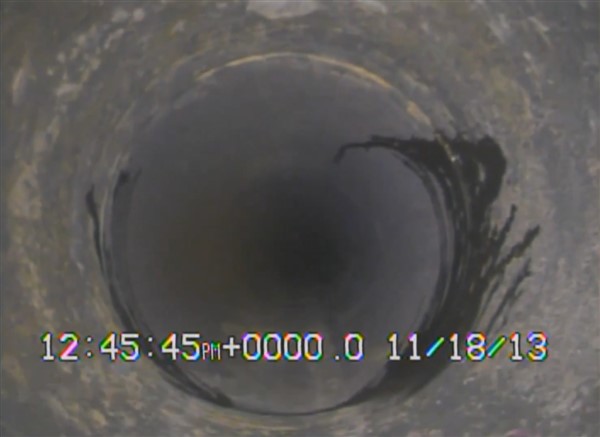

The picture below shows a pipe after cleaning, during pipe preparation and inspection. Scout is vaculating a joint of loose debris and standing water and quickly dries the pipe, preparing the joint and pipe for liner application.

Click on the video below to watch Scout vaculate the pipeline joint shown above in real time.

Vaculation of Pipeline Service Connections

The picture below shows Scout vaculating or drawing out standing water from a service connection during concurrent preparation and inspection of the pipe. The service connection is vaculated to help prevent water dripping from the service during the lining process helping to ensure a high quality liner application. The airstream quickly dries the pipe wall following vacualtion. The Scout can then quickly move to the next joint or service connection for further preperation and inspection.

Click on the video below to watch Scout vaculate and dry the service connection shown above in real time.

Scout helps to ensure the bond results you need for long-term, leak-free liner performance in those hard to clean areas such as joints, crevices and service connections.